Best-in-Class Carbide Supplier

Based in Barcelona, Spain, TEMSA is a full-range supplier of carbide components to the global manufacturing industry. Renowned for its unwavering commitment to quality and innovation, TEMSA specializes in a comprehensive range of carbide products, covering all areas of production from raw materials and process design to tooling manufacturing and installation processes. The company leverages advanced manufacturing techniques and a rigorous quality control process to deliver cutting-edge solutions that consistently exceed industry standards.

TEMSA recognizes that tooling performance is critical to the success of manufacturing operations. The company invests significantly in research and development, continually advancing the frontiers of carbide technology through collaboration with universities, technology centers, and research organizations.

A team of experienced engineers partners with customers to analyze their unique machining challenges and develop customized solutions that enhance productivity and efficiency. Its customer-centric approach, combined with a relentless pursuit of excellence, has solidified TEMSA’s position as a best-in-class carbide supplier trusted by manufacturers worldwide.

TEMSA specializes in producing tools with extremely tight tolerances, up to ±0.001mm. This level of precision is achieved using advanced CNC machinery and rigorous quality control processes.

TEMSA offers turnkey product development, from design to installation, ensuring efficient and timely solutions. This end-to-end approach ensures that clients receive efficient and timely solutions tailored to their specific needs.

TEMSA has consistently prioritized technology as the foundation for advancement, establishing the company as a global technological leader in the just-in-time manufacturing of specialized single-unit parts.

TEMSA has established a significant global presence, exporting over 70% of its production. This extensive commercial network allows the company to serve clients worldwide, providing high-quality tooling solutions across various markets.

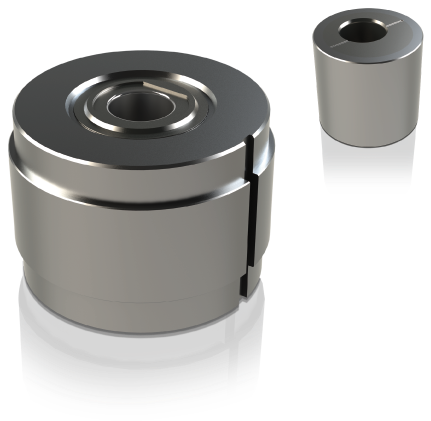

TEMSA possesses the advanced manufacturing capabilities and expertise to produce the most complex carbide tools with the most demanding tolerances, including:

This combination of factors allows TEMSA to consistently deliver carbide tools that meet the most demanding specifications, even for the most complex applications. Whether it’s intricate profiles, tight tolerances, or specialized geometries, TEMSA has the expertise and capabilities to produce tools that exceed customer expectations.

TEMSA’s customer-centric approach focuses on transforming unique machining challenges into tailored solutions. To fully understand customer needs and production environments, TEMSA collaborates closely to develop and deliver high-performance cutting tools that optimize productivity and efficiency through the following steps:

This iterative process, focused on continuous improvement and a commitment to exceeding customer expectations, ultimately translates customer requirements into tangible, high-performance cutting tools that drive significant gains in productivity, efficiency, and overall manufacturing success.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.