What is considered “small” to you? What are your needs and applications for small precision pin gages ? We are a precision small pin manufacturer, which means:

Our foundational capabilities are:

The three foundational capabilities are part of our core and what we do as a company very well. A large portion of the parts we manufacturer have one of these three core capabilities- either it’s small, it has a high surface finish or it has a precision tolerance..

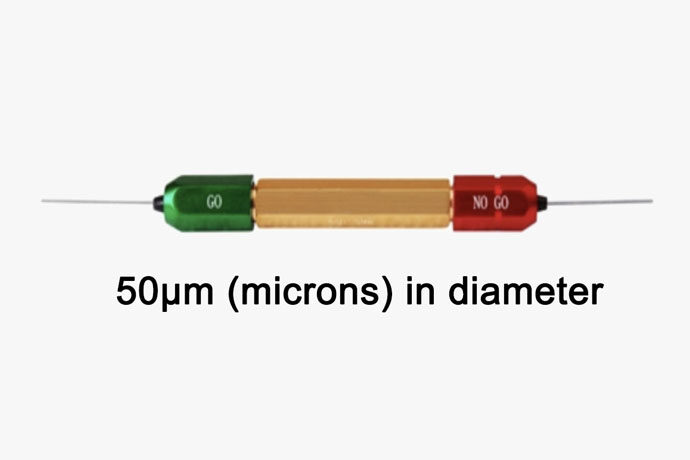

In recent months, our team has developed a process that is now allowing us to produce class X (+/-.00004” [.001016mm]) tolerance gages with an OD of .002″ (.0508mm). The machinists are not stopping there. They have had success in producing class XX (+/-.00002” [.000508mm]) gages down to .001” (.0254mm) OD and, are seeing encouraging results on gages down to .0008” (.02032mm) OD.

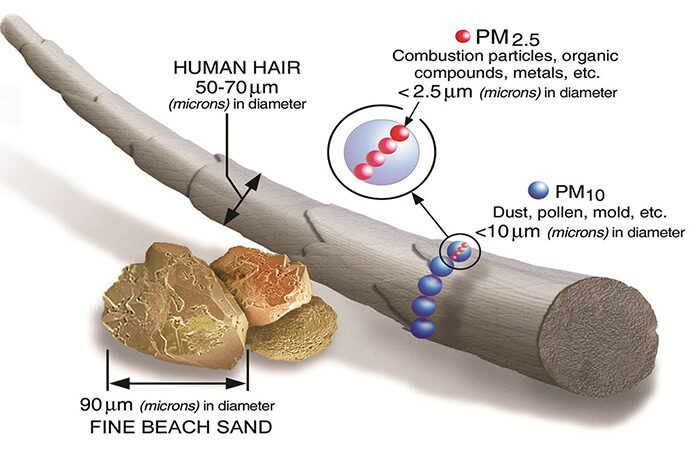

It’s hard to imagine the size of the parts and the precision of the tolerances we achieve.

The graphic to the right represents how small we are talking about in a relatable concept.

There are many applications for these small gages in the medical and inspection markets. In the medical world, small, precision pins are used to inspect the hole size of suture needles. Precision pins can be used to check the hole size, along with the suture tooling used by the needle manufacturers. Common sizes ordered are .008″ (.2032mm) and smaller. For inspection, small pins are used as probes and also as a checking device to inspect a hole or a depth. We have customer who request these precision pins in steels, carbides and sometimes ceramics. The OD size we can get down to, very much depends on the material we are using.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.