Precision Solutions provides custom application-specific products and cemented carbide components to meet your carbide mining demands. Hyperion Materials & Technologies designs and develops hard and super hard materials with extreme wear characteristics that will increase the overall performance of your products. A few of the materials used in mining applications include cemented carbide, diamond, polycrystalline diamond and Versimax® products.

The sealing of fluid dispensing components requires the mating of the actuator and the nozzle. Our Precision Solutions team will help you design these two mating features to achieve optimum performance.

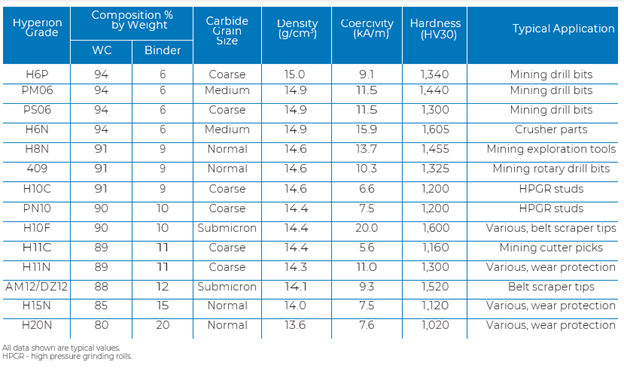

Hyperion’s materials are engineered to increase productivity and improve performance of our customers’ applications. We offer the largest range of tungsten carbide grades in the industry and have the ability to alter chemical properties for maximum resistance to wear, deformation, fracture, corrosion and oxidation.

We understand the aggressive environments equipment used in the mining industry faces. Corrosive, abrasive and impacting environments can require components and sub-assemblies that withstand these harsh conditions.

Precision Solutions manufactures high quality carbide buttons and tips for extreme performance in a variety of rock formations. We offer technical support for grade selection and button design to exceed our customers expectations.

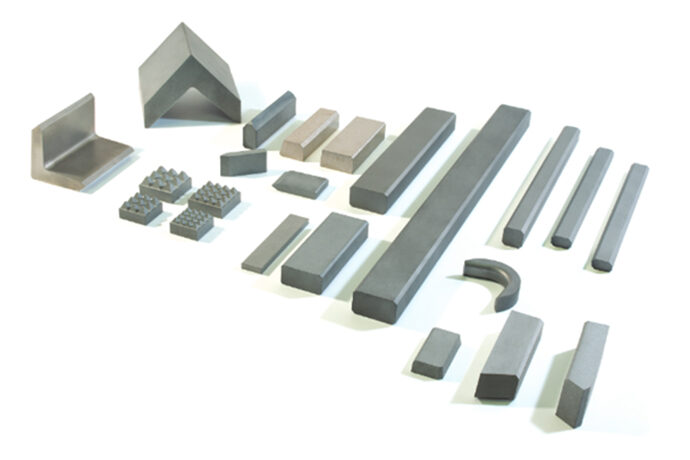

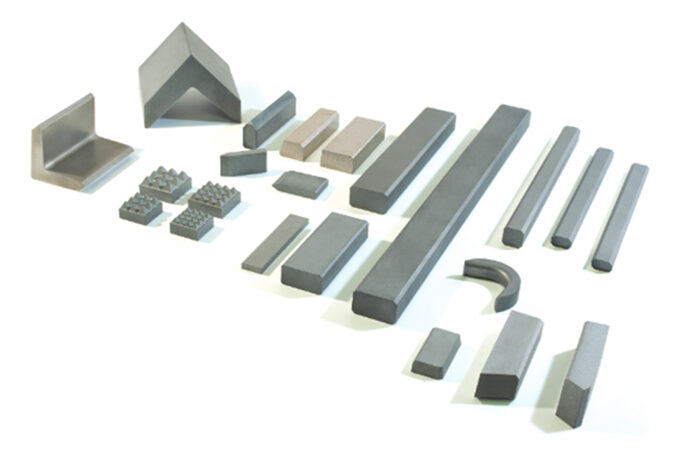

Cemented Carbide Components

The cemented carbides we develop are used for various wear protection applications in the mining industry. Our grades have undergone extensive research and development trials before establishing the final product. Many Hyperion cemented carbide grades for wear protection have been successfully used in scrapper blades for conveyors, carbide tips for bucket wheel excavator (BWE) teeth and jaw gripper pads.

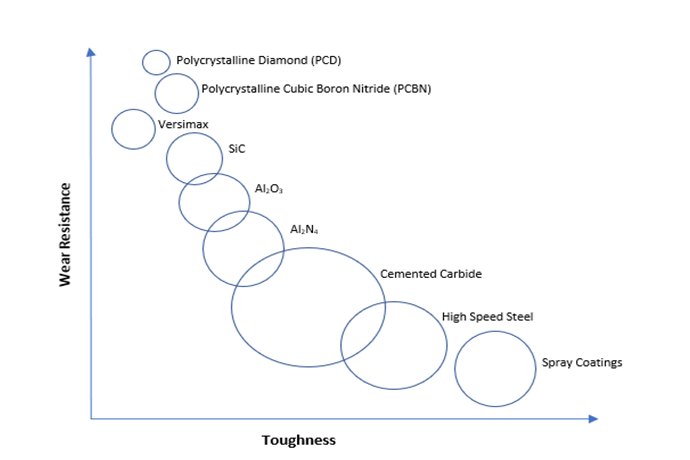

Versimax™ Components

Versimax™ is a Hyperion silicon carbide bonded polycrystalline diamond (PCD) composite with superior wear resistance and high strength and temperature performance. Versimax™ has been proven successful in many applications including nozzles, grinding centers where strength after high temperature exposure is needed and where excellent resistance and electrical conductivity is required.

Mechanical seal rings and other wear rings are manufactured to custom dimensions per application and customer requirement. Cemented carbide grades and designs are tailored to each customer based on individual needs and requirements. Hyperion Materials & Technologies manufactures cemented carbide mechanical seals that provide outstanding material performance in corrosive and abrasive environments. Hyperion seal faces help to minimize leakages by maintaining a stable sealing gap due to high mechanical strength and stiffness. Cemented carbide seal rings can be engineered to fit your specific needs. Additional information can be found here.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.