The strength and wear resistance of cemented carbide make it the best choice for precision aerospace components, as other materials cannot withstand the tough environmental conditions. The properties of cemented carbide allow it to adapt to conditions as equipment performance intensifies.

Hyperion Materials & Technologies has received the EN9100:2018 certification for our Epinouze, France location. Precision Solutions has received the AS9100 Rev. D certification at our GLE-Precision location.

Hyperion provides engineering expertise and manufactures other hard and super-hard materials used to produce precision aerospace components, including cubic boron nitride (CBN) and diamonds. Aluminum and steel components benefit from a much longer life if coated in our patented composite diamond coating. This coating can be applied to any shape regardless of intricacy and without line of sight.

After receiving the AS9100 Rev D. certification, the opportunities arose to work with creative leaders to produce what has been called ‘the unthinkable’ when it comes to precision tolerances on small parts and components for the aerospace industry. Gyroscoping and directional precision pins made from carbides and hardened steels are used in flight instrumentation. Whether providing directional applications for an airplane or a missile, the amount of accuracy that goes into precision manufacturing is the core of our business.

Custom drilling and counter sinking solutions are designed and manufactured for the machining of carbon fiber reinforced composite materials by the Precision Solutions team.

Modularity designed systems allows for the replacement of individual drills and countersink inserts at a dramatically reduced life-cycle cost when compared to integral designs.

Extended wear life is absolutely critical to production so that uptime is maximized and production time is minimized on multi-million-dollar Automatic Fiber Placement (AFP) machines and Composite Tape Laying Machines (CTLM).

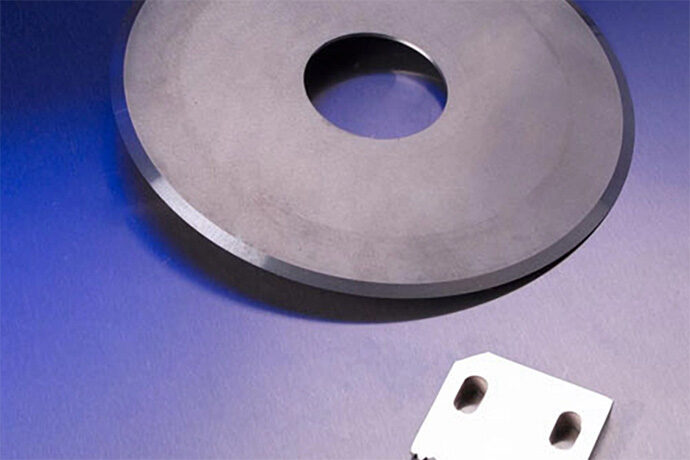

Leaving these high value machines idle due to unnecessary or premature tool wear is not an option. Crafts Technology has been producing cutters, cutting tools, knives, and other parts for use in the production of composite tape and the fabrication of composite materials since the early 1970s, when McDonnell Douglas was developing composites to reduce the weight of fighter aircraft.

We continue this tradition and leverage our legacy of experience in the aerospace industry, contributing to the efforts of the major aircraft producers to standardize composite technology on new generation commercial aircraft. Crafts Technology develops cutting implements to provide maximum value-add to our customers as they look to improve their competitiveness.

From precision grinding to lapping and engineering services, we provide exceptional customer service and expedited delivery options to all of our customers.